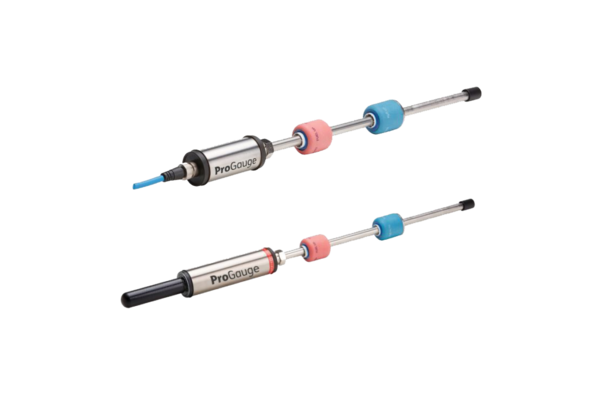

ProGauge Magnetostrictive Level Probes

ProGauge Magnetostrictive Level probes provide continuous and highly accurate readings of liquids inside of the tank. By transmitting a high frequency electrical impulse that travels at the speed of sound, the advanced technology within the probes is able to measure the time elapsed between the initial sending of the signal and its return to the float, giving an unbeatably accurate

fuel reading which is then relayed to the ProGauge console on site or directly to the Point of Sale (POS).

Wired or Wireless

Our wired probes are ideal for sites which already have the required cabling to enable easy installation and function. Benefitting from fast and reliable data transmission, our wired probes are suitable for both above and below ground tanks and are the product of choice for many operations across the globe.

ProGauge’s wireless liquid level probes are perfect for sites wishing to avoid expensive digging, wiring and cabling costs. Our wireless probes are able to transmit data up to 80 metres from underground tanks - a distance which can be extended to 800m with the aid of an additional above ground RF receiver - and are well-equipped and rigorously tested to manage environments where wireless coverage is typically limited. The ProGauge wireless

liquid level probes benefit from all of the same features as the wired probe.